HSV introduces Project+, Let’s make it FIT

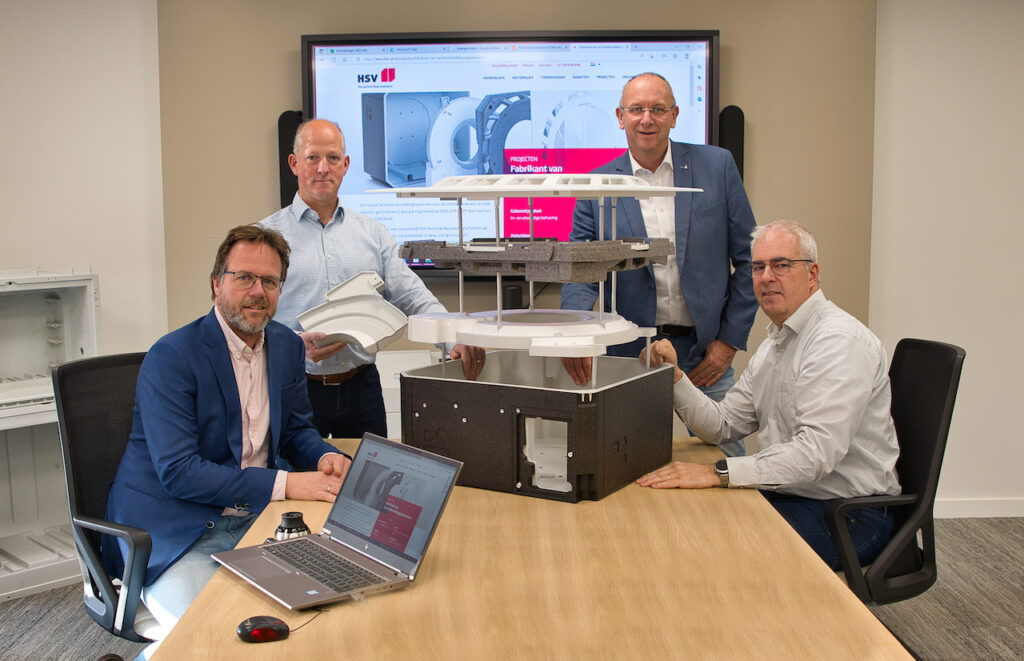

Project+ makes HSV the first manufacturer in Europe to successfully integrate large injection-moulded parts and EPS/EPP foam components.

Project+, engineering added value

Project+, Let’s make it FIT by HSV essentially means engineering added value.

HSV has years of experience in injection-moulded plastics and particle foam technologies, focused on developing, producing and assembling shaped composite plastic components on a large scal

We believe in sharing knowledge and finding answers that contribute to an optimal composite product for our customers. The Project+ approach gives you access to this expertise and our facilities. As a result, you can achieve savings during the design phase, or when redesigning a product.

Advantages of Project+, product design and redesign

As stated, Project+ helps you to optimise your product design and achieve savings. This approach also has proven added value for redesigning from metal to plastic.

Project+: how a composite product is structured

The key to success: the most efficient solution for your product is identified in partnership. A number of advantages of Project+:

- Ability to be shaped into any form at all

- Lower weight

- All plastic components fit in perfect alignment

- The minimum in components

- More effective and efficient logistics

- Sustainable product realisation

And that leads to:

- Optimised TCO

- Shorter time to market

- Lower costs

- Lower purchasing risks

Discover the benefits of free-form shaped components and achieve lightweight, thermal and structural innovations with Project+ at HSV. Thanks to the in-line assembly, separate components are limited to a minimum and you have a single point of contact. Besides the benefits of optimising TCO, this also shortens time to market for your product. In short: Project+ brings your plastic product concepts to life!

More about Project+

Scan the QR code and discover Project+ or call +31 318 248 748 to talk to one of our engineers about your specific question.

Scan the QR code and discover Project+ or call +31 318 248 748 to talk to one of our engineers about your specific question.