The particle foam engineers during ISH

Innovations for a sustainable future?

Discover it during ISH 2025

17 – 21 March 2025 | Hall 8 Stand number: D95

Messe Frankfurt | Frankfurt am Main, Germany

Sustainable, integrated development & production of large, technical components or redesign?

With Project+, Let’s make it FIT from HSV, you can benefit from our expertise in plastics, particle foam and injection moulding technology right from the design phase of your product.

We partner with you to identify the most efficient solution for your product.

HSV engineers Project+, Let’s make it FIT

The Project+ approach of HSV stands for: Smart innovation and streamlining through in-line assembly and highly effective logistics.

Project+ provides you with financial savings and simplifies the logistics process.

Click here and register for your visit.

Visit our booth: Hall 8 stand number D95

Visit us: Hall 8.0 stand number D95 and discover Project+ during ISH.

Our project team would also be happy to advise you about:

- The latest trends and innovations in particle foams and large injection-moulded products

- Smart, sustainable and cost-reducing solutions for your product design

- The added value of 3D shaping into any form

- Using recyclate for your sustainable product or component.

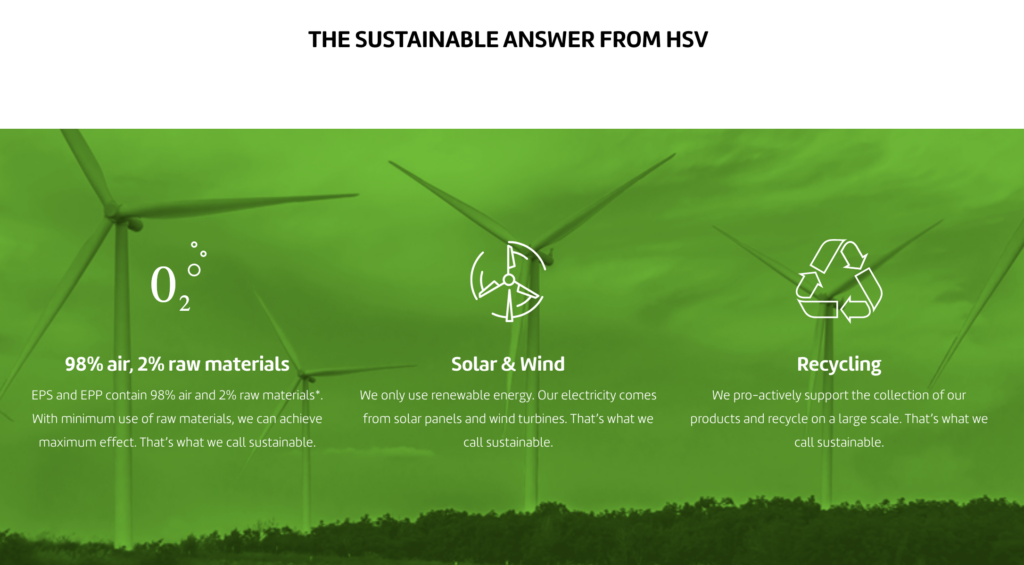

The focus at ISH is on future-driven topics, such as contributing to preserving natural resources and using renewable energy sources.

Location and route description:

Hall 8 Messe Frankfurt am Main | Germany

Parking garage Rebstock | Frankfurt am Main

The added value of HSV

Developing or redesigning a new plastic product starts with a good design. As early as the initial phase of the product design, you can call on the Project+ engineers at HSV.

Do you have a design question or would you like to assess the feasibility of your product design? Request a feasibility study.

You will receive advice without any obligations. You will gain insight into the options for your finished and/or semi-manufactured product, and find out how long production will take, accompanied by an initial estimate of the costs.

No time to visit ISH? Book a ThinkThank workshop at your location!

Discover more about Project+ and sustainable solutions of HSV

In addition, particle foams help us move forward in making our society sustainable. These expandable plastics contribute to saving energy, reducing CO2 emissions and combatting food waste. Particle foams consist of +95% air and are circular.