HSV: 50 years of innovation!

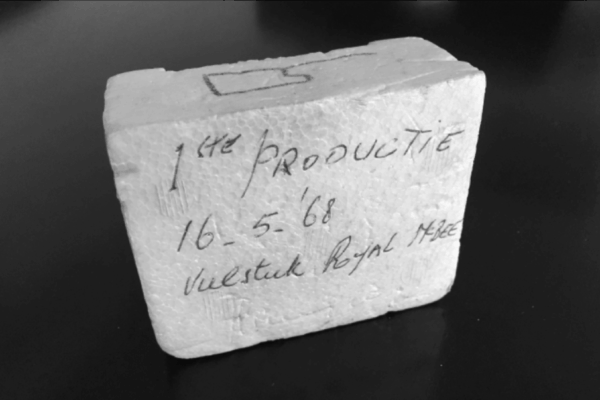

50 years ago – in May 1968, to be precise – the first piece of EPS (now known as airpop® engineered air) rolled off the production conveyor in Ede, marking the start of HSV!

From packaging material to technical solution | The added value of HSV

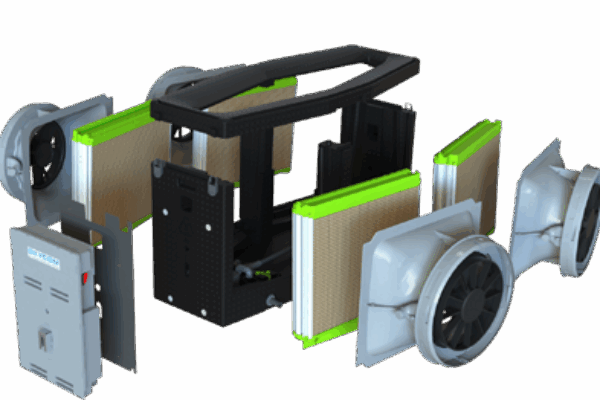

In a world that never stops changing, HSV has not been standing still. The organisation has developed from a production company generating packaging and building materials into a company operating internationally, specialising in engineering and producing innovative, lightweight particle foam products and semi-manufactured products, large injection-moulded products, and Project+ solutions. Its solutions yield countless advantages for its clients.

This innovative family firm is among the top 40 Dutch manufacturing companies. HSV develops and produces technical product solutions for a diverse range of markets, adapting its production and logistics to the preferences of its clients.

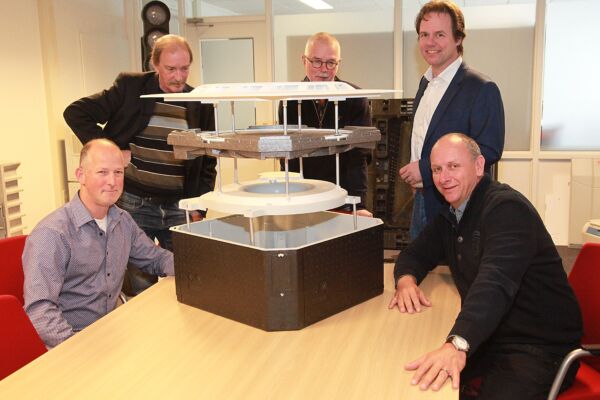

Project+ solutions | discover the hidden invention. by HSV

‘Project+ essentially means engineering added value for our clients,’ says Allard Lohman, managing director. ‘Optimising your product and simplifying assembly leads to direct cost savings, for instance.

HSV is the definitive producer in Europe that successfully achieves seamless alignment of hard plastic sections and particle foam components. This achievement is possible because we have the expertise, knowledge, and technology within our company to handle both techniques. Would you like to optimise your products more? Contact us, let us tell you more, and discover the hidden invention. by HSV.’

Savings in the supply chain and sustainable production

Another area of added value for HSV clients: using particle foams and injection-moulded sections helps you achieve savings throughout your supply chain. The HSV production factories are based on a circular system; production runs on green steam energy, and HSV actively contributes to the circular economy through recycling and reuse.