This large-scale supplier develops and manufactures products in the field of flue tubes, air supply and air distribution.

For one of their existing products, a ventilation system, they were looking for a structural solution that could replace metal components. With Project+, Let’s make it FIT, from HSV, the engineers optimized the design of this product by using both Neopor, EPP and PP.

The lower weight, the insulating properties and the design freedom of these materials present many advantages for our client. We also integrated a number of functions in this solution.

The Project+ approach of HSV is the key to succes; Integrating two technologies particle foam engineering and plastic injection moulding. HSV has the in-house expertise and production capacity to assist you. Combining functions is even easier, and in-line assembly limits the number of components to a minimum.

In addition, HSV offers the possibility to use recycled plastics and particle foam mouldings are produced with sustainable steam. EPP can be completely recycled, which is ultimately better for the environment and a circular economy. Together for a sustainable future.

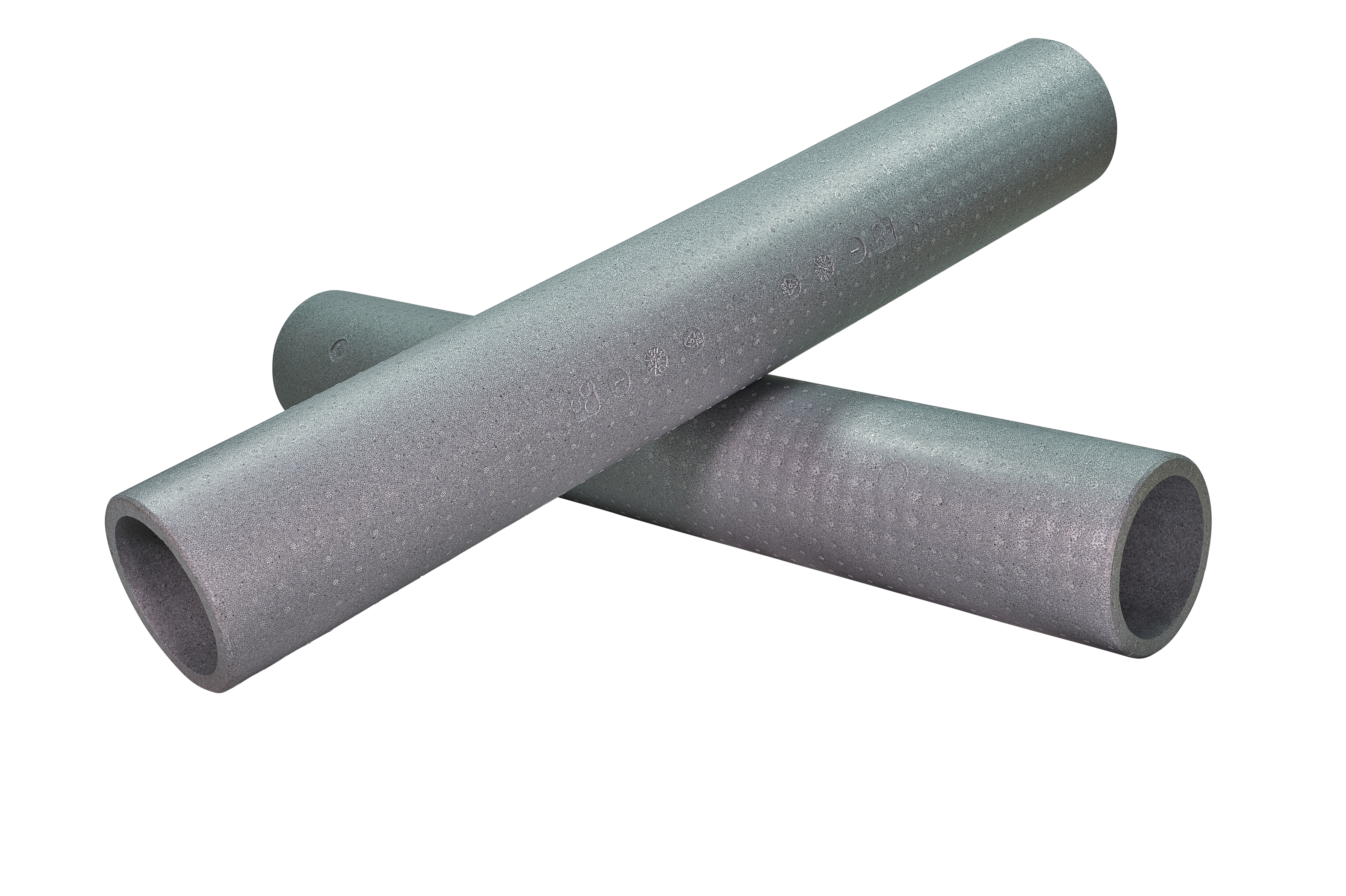

- Delivered product Housing, tubes and sockets as a Project+ solution

- Industrie Heating, ventilation and cooling (HVAC)

- Materials EPP, Neopor, PP

- Applications Air treatment - pipes / distribution systems for Balance ventilation system