Engineering added value

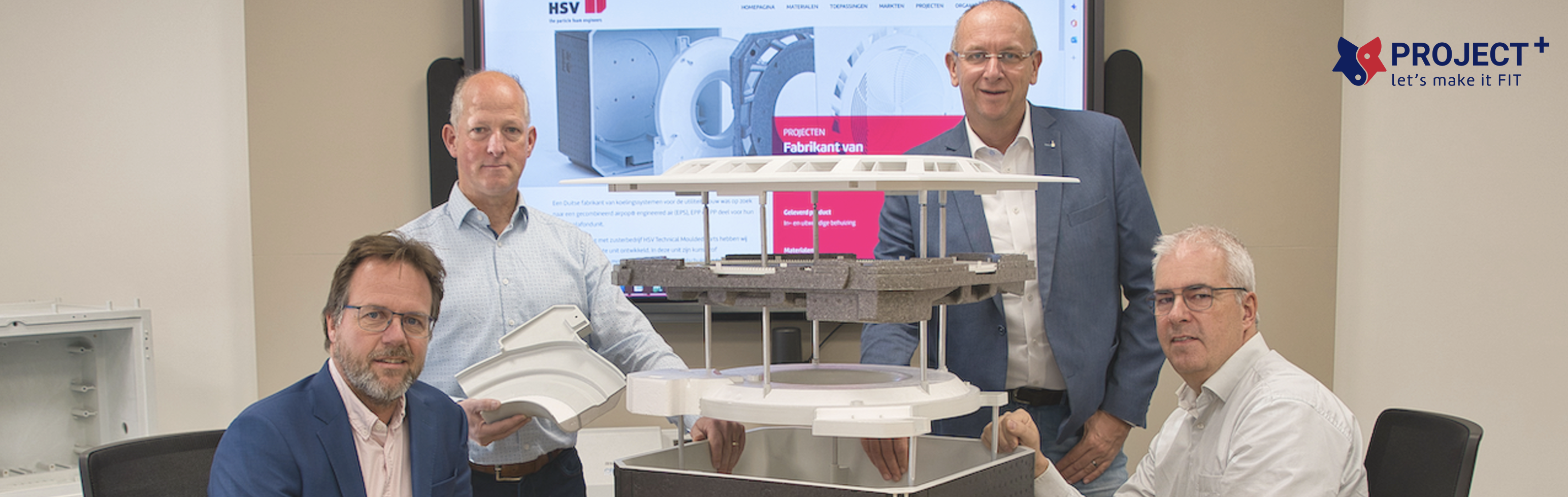

Project+ makes HSV the first manufacturer in Europe to successfully integrate injection-moulded and particle foam components.

Project+ at HSV means engineering added value for our customers. We achieve this through seamless integration of plastic injection-moulding technology (HSV Technical Moulded Parts nv) and particle foam technology (HSV Packaging & Insulation nv).

‘Project+, Let’s make it FIT brings you advantages and attractive savings.

Project+ is the most efficient solution

The Project+ approach: We partner with you to identify the most efficient solution for your product. Smart innovation and streamlining through in-line assembly and highly effective logistics are key. Project+ offers you the following advantages, among others:

- Shorter time to market

- The minimum in components

- Lower weight

- Lower costs

- More effective and efficient logistics

- Lower purchasing risks

- Sustainable product realisation

Project+ is suitable for optimising your product design or for redesigning your product from metal to plastic.

Would you like to optimise your product design now? The Project+ engineers at HSV are ready to help you.

Project+, Let’s make it FIT

Unique in Europe: designs based on injection-moulded components

The method used to design injection-moulded sections that are integrated with particle foam components is unique in Europe. It’s easy to explain why: there are hardly any companies that have in-house expertise in both techniques. In theory, the hybrid method could also be used by partnering with two different companies, but that process has proven to be much more difficult in actual practice. This is due to misaligned tolerances between the injection-moulded sections and the particle foam components.

As a result, even when both companies manage to maintain the required tolerances, it is very difficult to make components that seamlessly integrate the injection-moulded sections and the expanded particle foams.

At HSV, we say: Let’s make it FIT. Relying on the knowledge we have at our disposal, the Project+ engineers from HSV arrives at the intended solution, achieving seamless integration of the components. Would you like to know more? Ask one of our team members directly.

Project+ | Successful seamless integration

Project+ at HSV means benefits for you. Working closely with HSV, you can use Project+ to access expertise on plastic technologies and the in-house production and assembly facilities that HSV can offer.

All these factors contribute to seamless integration of injection-moulded plastic components and expanded foam components. The main issue here is not the tolerances, but whether the sections are functionally aligned and integrated. That is the core question that we address in partnership with you. It is a completely different approach.

Project+ at HSV gives you one point of contact

That’s what makes our solution so powerful: Project+ at HSV gives you one single point of contact. With our cocreative engineering capacity, we see the bigger picture and work in partnership with you to develop a comprehensive solution. Integration of both techniques – injection moulding and particle foam moulding – ensures that the advantages are optimally leveraged. Project+, Let’s make it FIT is made possible by over 100 years of engineering expertise sitting down at the same table: the Project+ engineers at HSV.

Project+ highly relevant for European OEMs

Under Project+, the first composite products were successfully developed for customers in the HVAC industry. But Project+ is also relevant for other European OEMs.

Project+ offers many opportunities and advantages

Project+ offers many opportunities and advantages for a wide range of applications. Examples include smart product solutions for agribusiness and horticulture, vertical farming, urban mobility, furniture and the aerospace industry, e.g. production of aircraft seating.

The growing demand for Project+ is unsurprising; HSV is increasingly being asked to optimise existing products and contribute to realising new products.

ThinkTank workshop

Do you have a design question? Or would you like to optimise your products and achieve savings? Call +31 318 648 999 to talk to one of our people, or book a ThinkTank workshop at your location.

The workshop has been developed especially for: technical directors, engineers, product designers and purchasing managers. Our ThinkTank workshop gives you a chance to discuss your latest product design questions and learn more about plastic technologies.

You will gain fresh insight into the world of Project+ and moulded plastics, and what this can mean for the development and production of technical components and products. If you schedule a workshop, the ThinkTank will drive to your location. You won’t even have to travel to get there – so efficient!

Project overview

Various Project+ reference cases are available here:

|

Internal & external housing for a ceiling unit |

Project+®, Let’s make it FIT is an initiative of and joint effort by HSV Technical Moulded Parts nv & HSV Packaging & Insulation nv.