Your product, manufactured sustainably

Your product, manufactured sustainably

Interested in having your product manufactured sustainably and reducing your costs? HSV the particle foam engineers offers the solution. By using particle foams and by achieving clever combinations of different material groups and production technologies, HSV offers you a wide-ranging, in-depth spectrum of product solutions. These product solutions are fully developed and manufactured for you at HSV. Our production facilities use sustainable steam and renewable energy. By using minimum amounts of raw materials, we develop products with the optimal qualities that you need, which can also be recycled again at the end of their life cycle. The use of particle foams is perfectly aligned with the circular economy.

Your product, manufactured sustainably

Are you looking for ways to achieve sustainable manufacturing for your product? High-quality materials that can fulfil the requirements for extreme material properties? Or lightweight construction components for internal and external applications?

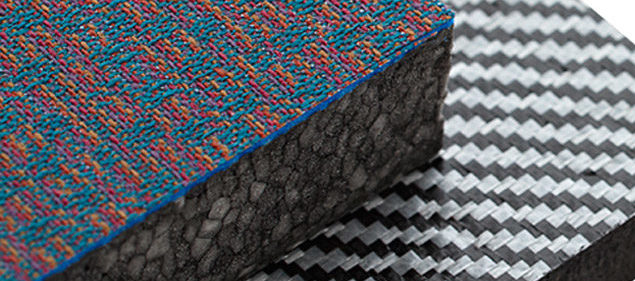

From design and manufacturing to assembly and just-in-time delivery, HSV the particle foam engineers has all the facilities and expertise you need, right within the company – and we contribute to sustainable product solutions that will save you money in countless ways. By using particle foams, you have complete freedom to create any shape at all for the design of your product, and the material has excellent insulating properties. Excellent shock-absorbing properties ensure maximum protection and the material is lightweight. Product combinations based on both hard and expandable plastics, Project+ solutions from HSV, are also possible. And particle foams are also infinitely recyclable.

The benefits of particle foams

The various benefits of particle foams at a glance:

- Complete freedom to create any shape at all, developed and tailored to your specific requirements

- Weight reduction

- Optimal shock absorption, able to handle massive kinetic energy, for optimal protection

- Lightweight and robust

- Sustainable and completely circular

- Easy to clean

- Considerable cost savings in transport and in your organisation’s logistical processes

HSV has obtained certificates for ISO 9001:2015 and ISO-TS 16949:2016.

HSV particle foams are used extensively in the automotive industry, the pharmaceutical and health care sectors, the fishing industry, the construction sector, HVAC (heating and ventilation), the electronics sector, the household appliances sector, the agricultural sector, the food industry, and art & design.

Discover the added value and exceptional potential of our materials and material combinations in the development and production of your sustainable product.